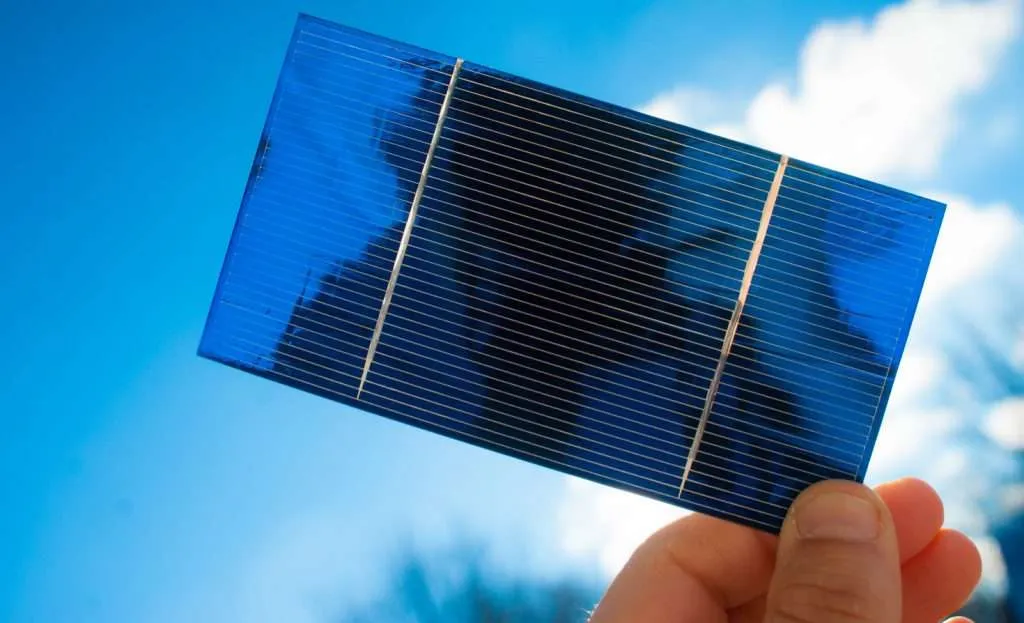

When you are purchasing solar panels there will be many different cell types for you to choose from, so what are those common solar cells? This is a guide for you to understand 3 most popular types of soar cell on the market and manufacturing.

What is solar energy?

Solar energy is actually the most dominant source of energy on Earth. Solar energy is the energy produced by the continuous process of nuclear fusion reactions inside the Sun. Although the energy radiated by the Sun to the outside of the Earth’s atmosphere is only one 2.2 billionth of its total radiant energy (about 3.75×10^14tw), its radiant flux is already as high as 1.73×10^5tw, which means that the energy projected by the Sun onto the Earth every second is equivalent to 5.9×10^6 tons of coal.

The vast majority of energy on Earth is derived from solar energy. Wind energy, water energy, biomass energy, ocean temperature difference energy, wave energy and tidal energy are all derived from the sun. In the past 20 years, solar energy has been widely used in people’s lives, and photovoltaic applications are developing rapidly.

What is the operating principle of Solar Cell?

The working principle of solar cells is based on the photovoltaic effect of the semiconductor PN junction. The so-called photovoltaic effect is when the object is illuminated, the state of charge distribution within the object changes and produces an electric potential and current effect.

The photovoltaic effect is closely related to the photoelectric effect and is an internal photoelectric effect. In the photoelectric effect, the material absorbs the energy of photons to produce some free electrons to spill over the surface.

And in photovoltaic effect, due to the inhomogeneity inside the material (for example, when PN junction is formed inside the material) under the action of self-built electric field, the excited electrons and the holes that lose electrons move in opposite directions, and the positive and negative poles are formed.

What is the main classification of Solar Cell?

In terms of the regularity of particle arrangement inside the crystal, crystalline silicon cells are classified into monocrystalline cells and polycrystalline cells. At present, monocrystalline cells have become the absolute mainstream in the industry, and are broadly classified into monocrystalline PERC structure, N-TOPCon structure, N-HJT structure, IBC structure and so on. Among them, PERC accounts for about 85%, which is also the main cell type of Sungold solar modules.

1、PERC crystalline silicon cells

PERC (Passivated Emitter Rear Cell) – Emitter and backside passivation cell technology, different from conventional cells is the backside, PERC cells use a passivation film to passivate the backside, replacing the traditional all-aluminum backside field, enhance the internal back reflection of light in the silicon base, reducing the This enhances the internal reflection of light from the silicon base and reduces the compound rate on the back side, thus increasing the efficiency of the cell by 0.5%-1%.

Currently, P-type monocrystalline cells have adopted PERC technology, with a thickness of about 180um, generally with the front side as the negative pole and the back side as the positive pole. Taking 22.8% efficiency cells as an example, each 182 cell has a power of about 7.53W, an open circuit voltage of about 687mV, a short circuit current of about 13.39A, an operating voltage of 597mV and an operating current of 12.61A.

PERC technology has been widely adopted by the PV industry because it delivers higher efficiency compared to conventional solar cells, with typical efficiencies exceeding 20%. This has made PERC cells a popular choice for solar panels, especially in residential and commercial applications. Because of the high cell conversion rate of PERC cells, the primary cells used in Sunlight Sungold solar modules are also PERC cells. They are used in Sungold flexible panels, rigid solar panels, and portable solar panels.

2、N-TOPCon crystalline silicon cells

TOPCon (Tunnel Oxide Passivated Contact) – oxide layer passivated contact. The front side is not fundamentally different from conventional N-type solar cells or N-PERT solar cells, and the core technology of the battery is the back side passivated contact.

The backside of the cell consists of an ultra-thin layer of silicon oxide (1~2nm) and a phosphorus-doped microcrystalline amorphous hybrid Si film, which together form a passivated contact structure.

The passivation properties are activated by an annealing process in which the crystallinity of the Si film changes from a mixed microcrystalline amorphous phase to a polycrystalline one. Annealing at 850°C with iVoc>710mV,J0 at 9-13fA/cm2 shows the excellent passivation performance of the passivated contact structure.

This structure can block the oligon hole compound and enhance the open circuit voltage and short circuit current of the cell. The ultra-thin oxide layer can allow multiple electron tunneling into the polysilicon layer while blocking oligon hole compounding.

The good passivation effect of ultra-thin silicon oxide and heavily doped silicon film makes the energy band on the wafer surface bend, thus forming a field passivation effect, which greatly increases the chance of electron tunneling and decreases the contact resistance, enhancing the open-circuit voltage and short-circuit current of the cell, thus improving the cell conversion efficiency. At present, there are two process technology routes, LPCVD and PEALD.

3、IBC crystalline silicon cells

IBC (Interdigitated Back Contact) – cross-finger back contact cell technology. The P/N junction, substrate and emitting area contact electrodes are made in the shape of crossed fingers on the back side of the cell.

Core technology: How to prepare good quality p- and n-regions arranged in forked fingers on the back side of the cell.

By printing a boron-containing forked-finger diffusion mask layer on the backside of the cell, the boron on the mask layer is diffused into the N-type substrate to form the p+ region, while the area where the mask layer is not printed is diffused by phosphorus to form the n+ region.

The front surface is prepared with a pyramidal fleece surface to enhance the light absorption, and a front surface field (FSF) is formed on the front surface. With ion implantation technology, the p- and n-regions can be obtained with good uniformity and precisely controllable junction depth.

However, the cost of IBC cells is high and has not yet been industrialized. The process of IBC cells is complicated, and semiconductor technologies such as masking and lithography are used many times, so the cost is almost twice that of conventional cells.As early as 16-17 years TNO propaganda P-type IBC structure.

p-IBC plus a LPCVD other compatible with PERC, laser a little difference, 90% compatible. p-IBC technology, is based on P-type silicon wafer. Positive efficiency has an advantage, at present, or biased towards single-sided, bifacial rate of less than 50%, positioned as a distributed product. p-IBC has the opportunity to cost close to PERC, efficiency to do up is 24.5%-25%, to achieve 1-3 cents / W cost gap.

If you want to know more about solar cell, more about Sungold, just click our website.