Welcome to our latest technological exploration! Today, we dive deep into the manufacturing process of shingled solar panels. Join us as we step through each precision-driven stage, from the initial el inspection to the final welding, and discover how cutting-edge technology shapes the future of solar energy. Let’s get started!

Initial Cell Inspection

The solar panel manufacturing process begins with the precise handling of solar cell wafers. These wafers are carefully picked up by machines equipped with advanced CCD cameras. These cameras play a crucial role—they scan each cell to detect any defects such as missing corners, black spots, or black flakes, a process enhanced by the photoluminescence (PL) effect.

Strict Quality Control

At Sungold Solar, we utilize these cutting-edge technologies to ensure that every solar cell entering the production line meets the highest quality standards. This method not only guarantees the high performance of our products but also significantly improves production efficiency.

Defective cells are immediately identified and segregated. They are sent to a specially designed storage box for defective products, ensuring that only the highest quality cells continue through the solar panel manufacturing process. This meticulous screening is crucial for maintaining the high standards of our solar panels.

Precision Alignment and Gluing

After passing the initial quality check, the cells move to the positioning platform. Here, machine alignment is executed with precision to ensure that each cell is perfectly positioned for the subsequent stages. The CCD camera comes into play again, conducting a second, more detailed scan. This time, it checks for hidden cracks, broken grids, and other less obvious defects that could affect the panel’s efficiency.

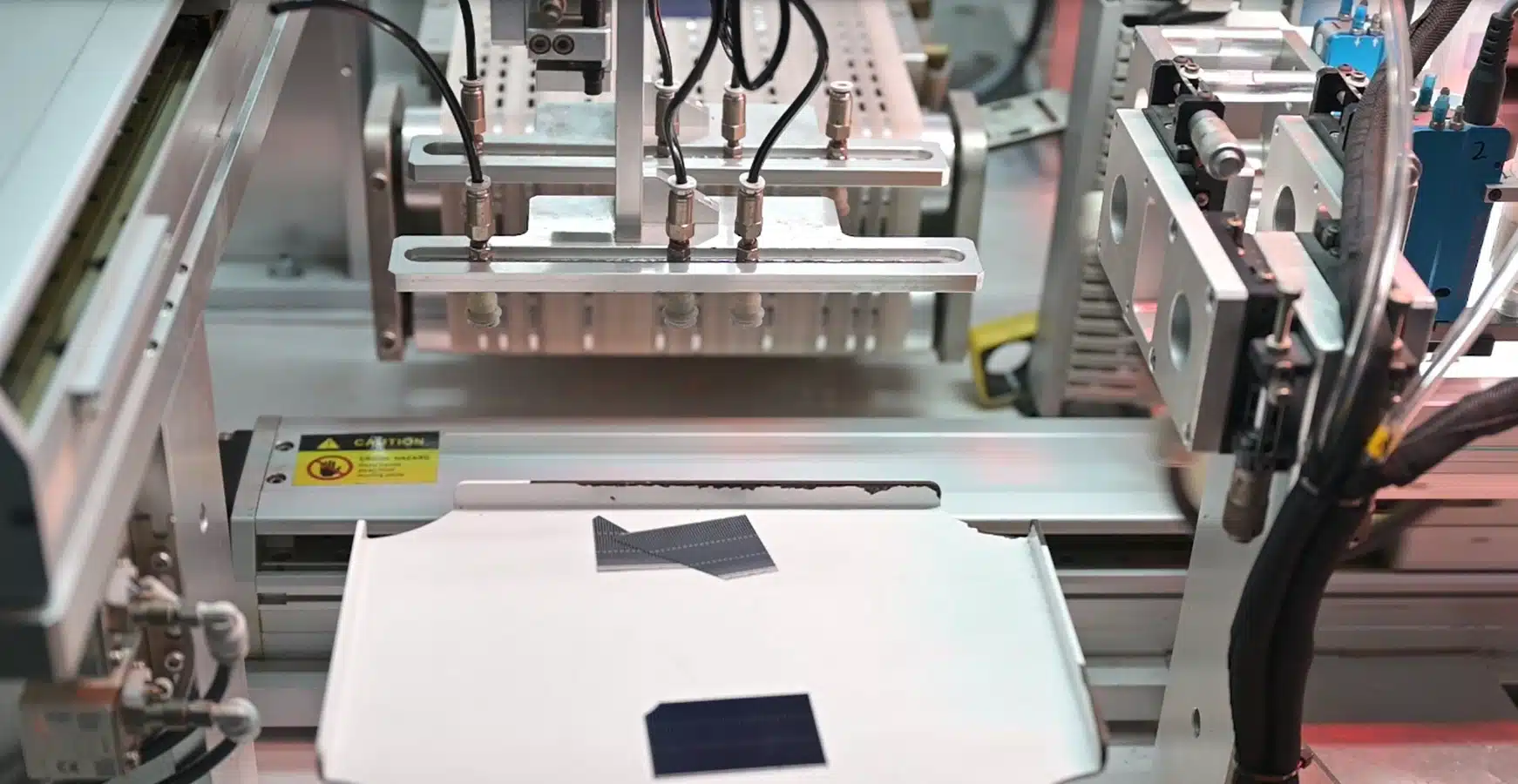

Cells that fail this second inspection are also sent to the defective product storage box. Those that meet all quality standards proceed to the next critical phase—gluing. At the gluing platform, cells are carefully coated with a conductive adhesive. This adhesive is crucial for the next step, as it facilitates the electrical connection between cells without the need for traditional bulky busbars.

Welding and Quality Assurance

The final solar panel manufacturing process takes place at the welding platform. Here, cells that have been accurately aligned and glued are permanently connected through a precise welding process. This step solidifies the electrical pathways and ensures the structural integrity of the solar panel.

How to Wholesale Solar Panels from Sungold

Through these high standards and innovative production strategies, Sungold Solar continuously pushes the boundaries of solar technology, providing reliable, efficient, and aesthetically pleasing solar solutions to customers worldwide. Our relentless pursuit of technology and strict quality standards keep us at the forefront of the solar manufacturing industry, also reflecting our firm commitment to supporting sustainable development.

Since its establishment in 2008, Sungold has been dedicated to the production of solar panels for 16 years. We are committed to providing B2B wholesale services and support OEM and ODM customization services, adhering to the philosophy of excellence in manufacturing to provide our customers with top-quality products. If you are looking to wholesale solar panels or need assistance finding a distributor in your area, please feel free to contact us.