With the development of renewable energy sources, photovoltaic power generation has become an increasingly popular choice. The quality and performance of photovoltaic products are the key to the future development of the industry.

How to test a solar panel?EL inspection & EL testing is a very important quality testing technique for photovoltaic products, especially PV modules.

This article will introduce and analyze two main solar panel tests: EL inspection and EL testing.

What Is EL Inspection and EL testing?

EL Inspection and EL Testing are terms commonly used in the field of photovoltaics (solar cells) and electronics. They stand for Electroluminescence Inspection and Electroluminescence Testing, respectively.

Electroluminescence Inspection (EL Inspection)

Electroluminescence is the phenomenon where a material emits light when an electric current passes through it.

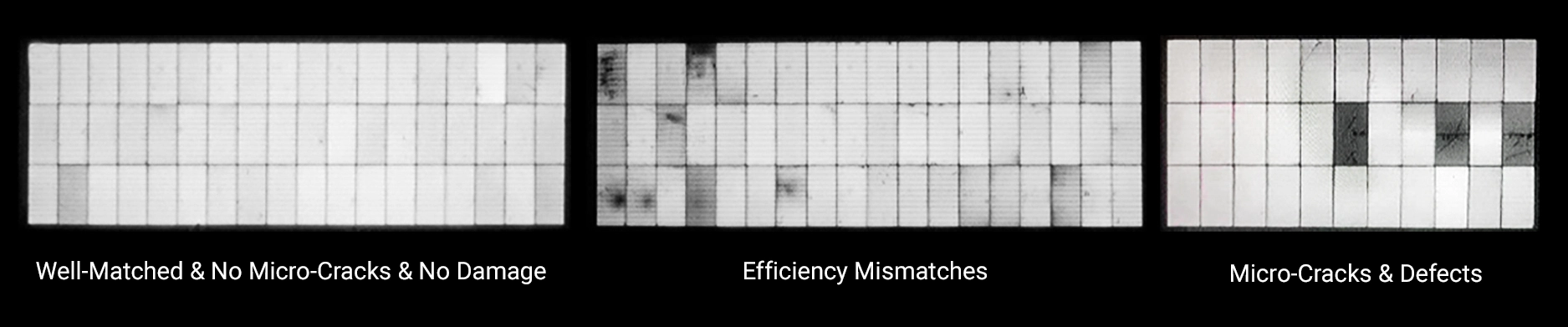

In the context of solar cells, EL Inspection involves capturing images of a solar module (a collection of solar cells) using a specialized camera in low-light conditions while applying a reverse bias voltage to the cells. This technique is used to identify defects, cracks, and areas of reduced efficiency in solar cells.

PV Module Inspection is crucial in the quality control and assessment of solar panels. It can reveal hidden defects that are not visible under normal lighting conditions. Defects such as microcracks, broken gridlines, and areas with reduced or non-functioning cell capacity can all be detected using this method. By identifying these issues early, manufacturers can ensure that the solar panels they produce are of high quality and will perform well over their operational lifetime.

Electroluminescence Test (EL Testing)

El testing is the process of assessing the performance and quality of solar cells or modules using electroluminescence.

This Photovoltaic Panel Testing method helps to identify and analyze defects, hotspots, and irregularities in solar cells and modules that might affect their efficiency and longevity.

During EL Testing, solar cells are subjected to a reverse bias voltage, causing them to emit light. A specialized camera captures images of the emitted light patterns. These images can then be analyzed to detect variations in the intensity of light emission, which can indicate defects, cracks, or areas with reduced electrical activity.

EL Testing is a non-destructive method that allows for the assessment of solar cells and modules without damaging them.

What is the EL inspection for?

What are some of the common defects that can be detected during photovoltaic (solar cell) manufacturing using electroluminescence (EL) testing?

- Microcracks: Tiny cracks in the surface or material of a solar cell can affect the structural integrity and performance of the cell.

- Cell Cracks: Similar to microcracks, these cracks appear inside the solar cell and can lead to performance degradation and potential failure.

- Soldering Defects: Problems with the soldering process used to connect components can lead to poor electrical connections and reliability issues.

- PID Defects: As mentioned earlier, Potential Induced Degradation (PID) can occur in PV modules, causing performance degradation due to voltage stress.

- Diode failures: Diodes are electronic components that allow current to flow in one direction. If they fail, they can disrupt the function of the circuit.

- Dead Cell: A solar cell that has completely lost its ability to generate electricity, usually due to a manufacturing defect or physical damage.

- Backsheet Scratches: Scratches on the back sheet of a solar module affect the aesthetics and structural integrity of the module and can lead to moisture penetration and electrical problems.

- Wafer Defects: Silicon wafers are the base material for solar cells. Defects on the wafer, such as impurities or irregularities, can affect solar cell performance.

PV Module Inspection identifies these defects by analyzing the EL Image Analysis of the PV cell. This non-destructive testing technique involves applying a voltage to the solar cell to capture the emitted light, which reveals structural defects and electrical anomalies.

Early detection of these defects through EL testing & EL inspection before the PV module lamination process helps to ensure the quality and reliability of solar panels before they are put into service.

What is EL testing?

EL testing is a non-destructive solar panel testing method for photovoltaic products, the full name of the EL test is Electroluminescence (electroluminescence) test. By applying a certain voltage on the PV panel, reverse current occurs at all PN junctions in the PV panel, resulting in electroluminescence, thus obtaining the image information on the surface of the PV panel, and then judging the quality of the cells in the solar panel manufacturing process.

Significance of EL testing

Detection of product defects: Solar Module Quality Check can directly reflect the defects and damage inside the PV panel. For example, defects such as micro cracks, pot cracks and poor metal wire contact of PV panels will be shown in EL testing.

Improving product quality: EL testing is a fast and accurate quality inspection method that can detect defects in time and thus improve the quality of the product.

Reduce maintenance costs: EL testing can detect defects in products in time, which can avoid bigger problems in the process of use, thus reducing maintenance costs.

Principle of EL testing

The principle of EL testing is to use the photoluminescence phenomenon to collect the reverse current through the interior of the battery and then image it through the corresponding optical system.

To perform the EL test, the PV panel is placed on the EL inspection equipment and a reverse voltage is applied to the PV panel, which causes the PN junction to generate a reverse current, resulting in electroluminescence. The light source will illuminate the EL, resulting in a visible image, which will be captured by the camera and processed to obtain the image information of the PV panel surface.

Importance of EL testing

EL testing can detect defects, damage, and flaws on the surface and inside the module by looking at the electroluminescence image of the module.

Detecting quality: EL testing can detect internal defects and surface imperfections in PV modules, enabling early detection of module quality problems, and thereby reducing the damage and impact of quality problems.

Improving performance: EL testing can identify damaged or defective cells in modules and timely identification and replacement of faulty cells can effectively improve module performance and efficiency.

Enhanced reliability: Electroluminescence (EL) testing for PV modules allows for a comprehensive quality inspection of PV modules before they leave the factory, reducing the failure rate and maintenance costs caused by quality issues and improving module reliability and lifetime.

Meeting standard requirements: EL testing is one of the standard test methods for PV module quality inspection and meets the requirements of international and national standards to ensure the quality and safety of PV modules.

Quality control during solar panel production can identify and address microcracks before the module leaves the factory, but after the module leaves the production line. Determining the cause of new damage (damage caused during transportation or improper installation) is critical to successfully obtaining a manufacturer’s warranty claim, workmanship claim, or self-coverage.

Electroluminescence (EL) testing identifies microcracks in components and helps to identify the root cause.

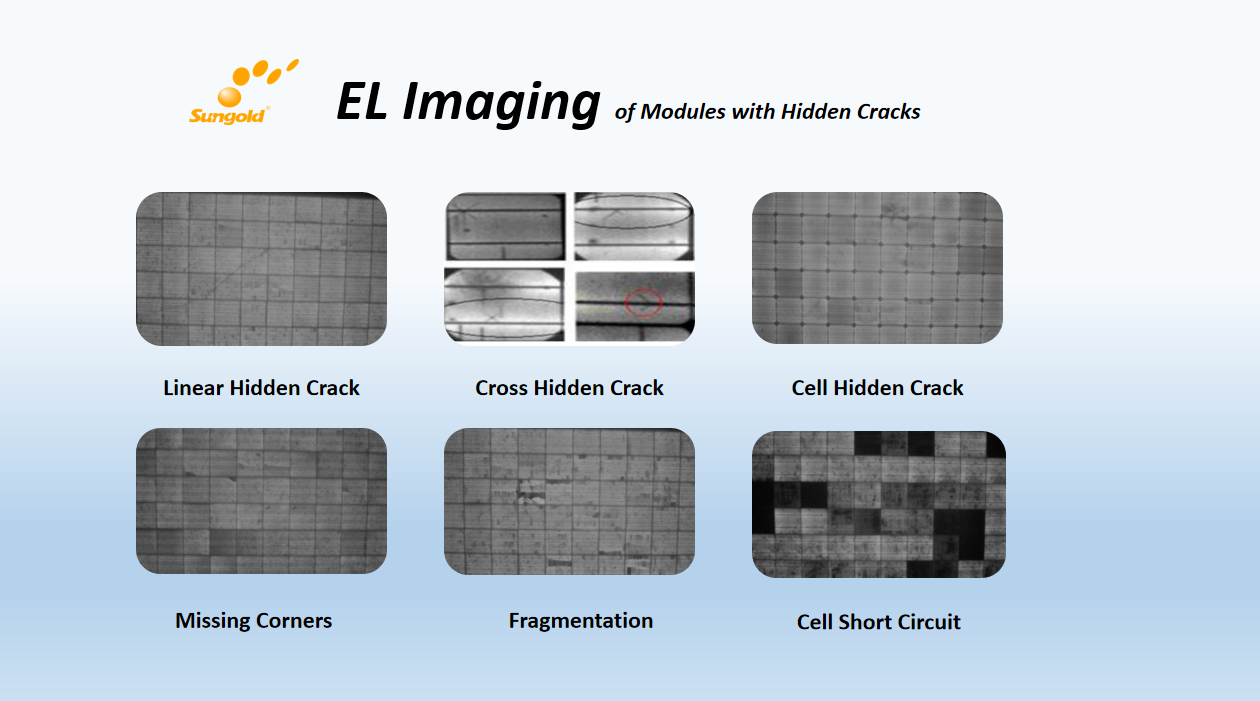

Common terminology for hidden cracks in modules

- Linear Hidden Crack: Starting from the edge of the cell, the main grid line, or the location of the rounded corner (chamfer), the crack extends in a straight line at about 45°, and the crack and the surrounding area are dark or there is no obvious abnormality in the area near the crack. Crack length across two main grid lines or more than 1/3 of the distance between two main grid lines.

- Cross hidden crack: In a certain area of the cell, two obvious black lines extend outward in the shape of a cross, or take a point on the main grid as the starting point, and the two black lines extend outward at nearly 90°.

- Missing corners: Refers to the triangular black area presented in the corner position in the EL image, but in the appearance of the inspection, this area does not show defects.

- Fragmentation: Cells show sharp triangular or irregular black areas, and the whole cell EL appearance is very poor.

- Cell mixing: Differences in electrical performance parameters between batteries result in very significant differences in brightness and darkness in the EL image.

- Cell short circuit: Single cells or multiple cells are not illuminated at all in the EL image.

- Area grid break: The phenomenon of straight black areas appearing along a thin grid in a cell EL image.

How to Test A Solar Panel By Other Testing

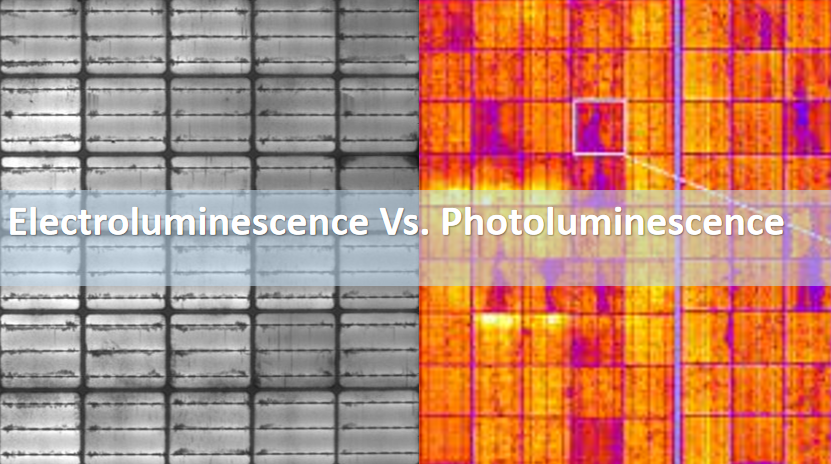

In addition to EL inspection and EL testing, PL testing is also a useful Solar Module Quality Check.

What is PL testing? PL testing, also known as Photoluminescence testing, is a solar panel testing technique used to evaluate the quality and performance of photovoltaic (PV) modules, which are commonly referred to as solar panels. PV modules are designed to convert sunlight into electricity, and their efficiency and reliability are crucial for their overall performance in solar power systems. Photoluminescent testing is one of the methods employed to assess the integrity of the solar cells within these modules.

How does photoluminescence work? The electrons in the semiconductor are excited by absorbing external photons. Electrons in the excited state are unstable and can jump to lower energy levels, releasing energy in the form of optical radiation, which is then captured and converted into an image by a CCD camera. PL test is mainly used to detect the distribution of impurities and defects in the cell, and to systematically analyze the causes of the reduction of the life of the lesser, PL test can detect and analyze each process link of the silicon wafer, fluff, diffusion, etching, coating, printing, sintering and so on.

FAQS

What is el tester?

El tester is a portable electrical instrument that can measure active or passive electrical magnitudes, such as currents, voltages, resistances, capacities, and others. It is also known as a multimeter or a polymeter. It is based on the use of a very sensitive galvanometer that is associated with different internal circuits to perform each measurement.

How does El imaging work?

EL imaging, or electroluminescence imaging, is a technique that can be used to detect defects and faults in photovoltaic (PV) modules and systems. It is based on the principle that when a PV cell is exposed to a direct current, it emits light in the infrared spectrum that a camera can capture.

EL imaging can reveal problems such as micro cracks, dead zones, poor soldering, and potential-induced degradation (PID) that may affect the performance and durability of PV modules and systems. EL imaging can be performed at different stages of the PV life cycle, such as during manufacturing, installation, operation, and maintenance.

EL imaging requires a dark environment and a direct current source to induce the electroluminescence effect. The current should be close to the maximum power point of the PV module or system. The camera should be sensitive to the infrared wavelength range and have a high resolution and dynamic range. The image quality may also depend on factors such as temperature, humidity, and exposure time.

EL imaging is a valuable tool for quality control and fault diagnosis of PV modules and systems. It can help identify defects that are not visible to the naked eye or with other methods such as visual inspection or infrared thermography. EL imaging can also provide information about the location and severity of the defects, which can help with repair or replacement decisions.

What is the full form of EL in solar panels?

EL stands for electroluminescence, which is a phenomenon that occurs when current passes through photovoltaic (PV) cells, causing them to emit light. EL testing is a method of detecting hidden defects in the structure of PV cells, such as microcracks, cell cracks, soldering defects, and diode failures. EL testing can help evaluate the quality and performance of solar panels by making the current distribution visible in the module. EL testing is usually done in a dark environment with a special camera that captures the light emitted by the PV cells.

Ensuring Unmatched Quality: Our Rigorous Solar Panel Testing Process

At Sungold Solar, we are committed to providing only the highest quality solar panels, which is why every panel undergoes a meticulous manufacturing and testing process. Our priority is to ensure that every solar panel we produce meets our stringent standards for performance and reliability.